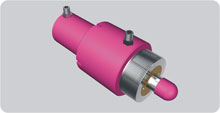

Hydraulic Cylinder

Hydraulic Cylinders manufacturer

Qualified hydraulic cylinder with enconomical costs

www.hc-hydraulic-cylinder.com

Hydraulic cylinder manufacturers--HC news

Today, a purchase manager Jianjun Liu from Wirtgen Machinery Co., Ltd. come to HC Hydraulic Cylinder Co., Ltd.

Last few days, I got a phone from Jianjun Liu, he said, I know your company from website, and know you are one of the best companies production hydraulic cylinder in China. So I want to get some information about you. Then I send a form to him. After he got some basic information about our company, they can't wait to come to some on-site inspection. Just now, our general manager received them and have a happy talking.

As is known to all, Wirtgen Machinery Co., Ltd is a very famous machinery manufacturer. and their quality is always the best.

We are looking forward to cooperating with them.

Warmly welcome purchasing manager Jianjun Liu come and visit HC.

Last few days, I got a phone from Jianjun Liu, he said, I know your company from website, and know you are one of the best companies production hydraulic cylinder in China. So I want to get some information about you. Then I send a form to him. After he got some basic information about our company, they can't wait to come to some on-site inspection. Just now, our general manager received them and have a happy talking.

As is known to all, Wirtgen Machinery Co., Ltd is a very famous machinery manufacturer. and their quality is always the best.

We are looking forward to cooperating with them.

Warmly welcome purchasing manager Jianjun Liu come and visit HC.

Kewords :

The hydraulic cylinder self-locking divides into the oil duct self-locking I the mechanical self-locking. The oil duct from is also installs the valve to carry on guarantees the pressure, enables cylinder's hydraulic fluid not to return to the fuel tank, in the oil cylinder oil cavity fills certain pressure fat liquor. But this kind guarantees presses the type self-locking is not very safe reliable, if has the divulging plunger slowly to return to the position. The mechanical self-locking namely installs the nut on cylinder's plunger, when after the cylinder rises the position which requests, cylinder plunger's on nut revolving, with the cylinder cylinder body contact, such plunger will be fixed arrives requests highly. When needs the release of pressure turns on lathe again the nut, lets the plunger return to the position. This kind of cylinder has the special name, is called the self-locking hydraulic cylinder.

Kewords :

Because the hydraulic technique has many merits, from civil to the national defense, from the general transmission to the close regulation, obtained the widespread application. In the mechanical industry, the engine bed transmission system has 85% to use the hydraulic transmission and the control at present, like rubs, the mill, to dig, to pull, and the combination lathe and so on; In the engineering machinery, has used the hydraulic transmission generally, like excavator, tire car loader, automobile starter, caterpillar band bulldozer, voluntarily-like carry-scraper, road roller, bulldozer and so on; In the farm machinery, has used in the combine, the tractor, the tool suspension system at present; In the automobile industry, the hydraulic brake, the hydraulic pressure self-discharging, the aerial ladder and so on obtains the widespread application; In the metallurgical industry, like the electric stove control system, mill's control system, the handwarmer feed, the converter control, the blast furnace control and so on; In light textile industry, such as injection molding machine, rubber vulcanizing machine, paper mill, printer, textile machinery and so on; In the shipbuilding industry, like entire hydraulic pressure dredge boat, salvage ship, production platform, wing ship, hovercraft and marine auxiliaries and so on. In the defense industry, the army, navy and air forces three services' many weaponry has used the hydraulic transmission and the control, like airplane, tank, artillery, missile and rocket and so on; In brief, all project domain, everything has mechanical device's situation, may use the hydraulic technique, the use domain and the equipment is getting more and more wide, are getting more and more.

Kewords :

1) to grasp the raw data and design basis, including: the use of the host and working conditions; working bodies of the structural characteristics of the load conditions, stroke size and movement requirements; hydraulic system on the selected operating pressure and flow; materials, parts and processes of reality; relevant national standards and technical norms.

2) According to the action asked to select the host type and structure of the hydraulic cylinder form.

3) According to the hydraulic cylinders are exposed to the external load force, such as gravity, friction and external kinematic, inertial force and the work load, to determine the hydraulic cylinder on each stage in the itinerary changes of the load power and the need to provide value.

4) According to the hydraulic cylinder of the work load and work of selected oil pressure, determine the diameter of the piston and piston rod.

5) According to the velocity of the hydraulic cylinder, piston and piston rod diameter, determine the pump flow.

6) Select the cylinder material, calculate the diameter.

7) Select the cylinder head structure, calculation of the cylinder head and cylinder connection strength.

8) According to the work schedule requirements, determine the maximum working length of the cylinder L, typically L> = D, D for the rod diameter. As the piston rod slender, longitudinal bending strength should be checked and the stability of the hydraulic cylinder calculation.

9) When necessary, buffer design, exhaust and dust and other devices.

10) Draw the hydraulic cylinder assembly drawings and part drawings.

11) finishing the design calculations, approval drawings and other technical documents

2) According to the action asked to select the host type and structure of the hydraulic cylinder form.

3) According to the hydraulic cylinders are exposed to the external load force, such as gravity, friction and external kinematic, inertial force and the work load, to determine the hydraulic cylinder on each stage in the itinerary changes of the load power and the need to provide value.

4) According to the hydraulic cylinder of the work load and work of selected oil pressure, determine the diameter of the piston and piston rod.

5) According to the velocity of the hydraulic cylinder, piston and piston rod diameter, determine the pump flow.

6) Select the cylinder material, calculate the diameter.

7) Select the cylinder head structure, calculation of the cylinder head and cylinder connection strength.

8) According to the work schedule requirements, determine the maximum working length of the cylinder L, typically L> = D, D for the rod diameter. As the piston rod slender, longitudinal bending strength should be checked and the stability of the hydraulic cylinder calculation.

9) When necessary, buffer design, exhaust and dust and other devices.

10) Draw the hydraulic cylinder assembly drawings and part drawings.

11) finishing the design calculations, approval drawings and other technical documents

Kewords :

The province, district and international businesss leaders accompanied by CEO Jun Lee of HC come to the company visits, research. At last, they gave us some precious words.

written by: Candy

email: service5@hc-hydraulic-cylinder.com

written by: Candy

email: service5@hc-hydraulic-cylinder.com

Kewords :

Hot runner mold design is made to put into injection molding machine production, the choice of injection molding machine is quite important also. All of the injection molding machine automatic cycle ability, applicable to hot runner system. In the choice has the following relevant factors injection molding machine to consider:

1 the addition of hot runner hot runner mold, more block flow plate, so a corresponding increase in the thickness of the mold, pay attention to select the injection machine installation height.

2 measurement of the volume of injection molding machines, to take into account the large volume of plastic flow in compression.

3the depreciation for the hot runner mold, injection molding machine to promote the continuous operation, start to reduce the use of multi-stage cycle.. Number of devices used to ensure the automatic operation of the mold, the first choice is easy to control the robot or the robot, such as:

1)the need to place the product insert, label or sheet until the mold.

2) extrusion of plastic parts or accelerate their ejection.

3) control the movement of plastic parts and accessories to reduce the startup time.

4) heat the mold before starting the injection molding machines .

1 the addition of hot runner hot runner mold, more block flow plate, so a corresponding increase in the thickness of the mold, pay attention to select the injection machine installation height.

2 measurement of the volume of injection molding machines, to take into account the large volume of plastic flow in compression.

3the depreciation for the hot runner mold, injection molding machine to promote the continuous operation, start to reduce the use of multi-stage cycle.. Number of devices used to ensure the automatic operation of the mold, the first choice is easy to control the robot or the robot, such as:

1)the need to place the product insert, label or sheet until the mold.

2) extrusion of plastic parts or accelerate their ejection.

3) control the movement of plastic parts and accessories to reduce the startup time.

4) heat the mold before starting the injection molding machines .

Kewords :

With the increasing demands for product appearance,electrical and electronic plastic parts become more complex in structure but also to keep the small size of the development. Precision injection molding technology in this area played a major role in the advanced precision molding technology greatly improves the quality of plastic parts, reliability, performance, reduce production costs and improve production efficiency, has great significance.

Injection technology is a method of manufacturing plastic products, the use of pressure injection of molten plastic into the plastic mold, cooling forming a variety of plastic parts you want to get a technical. Currently the most commonly used plastic is polystyrene. According to the International Mould & Plastic Hardware Industry Suppliers Association official Luo Baihui introduced, with the "3C" product development, precision injection molding precision injection molding machine as a key basic equipment, the size of the molding product repeatability, internal quality and repeatability and forming the three aspects of efficiency has been greatly improved. Compared to conventional injection molding equipment, precision injection molding machine really introduced for precise control products and precision production. Precision injection molding of plastics unit is to improve the quality of plastics, injection repeatability and quality of products within the three key components. Currently, the device mainly to the high-speed, high-voltage and fast response of the target development.

Injection technology is a method of manufacturing plastic products, the use of pressure injection of molten plastic into the plastic mold, cooling forming a variety of plastic parts you want to get a technical. Currently the most commonly used plastic is polystyrene. According to the International Mould & Plastic Hardware Industry Suppliers Association official Luo Baihui introduced, with the "3C" product development, precision injection molding precision injection molding machine as a key basic equipment, the size of the molding product repeatability, internal quality and repeatability and forming the three aspects of efficiency has been greatly improved. Compared to conventional injection molding equipment, precision injection molding machine really introduced for precise control products and precision production. Precision injection molding of plastics unit is to improve the quality of plastics, injection repeatability and quality of products within the three key components. Currently, the device mainly to the high-speed, high-voltage and fast response of the target development.

Kewords :

Seals lost effectiveness:

On one hand, hydraulic cylinder seal leakage. Because seals were wearied after long time working, or the cylinder and rod were wearied. From this point, the seals with best quality is very significant.

On the other hand, hydraulic cylinder creeps. The reasons are the valve is too small, or the designed rod speed of the hydraulic cylinder is slower and flow is small. Even though the valve is fit, the hydraulic cylinder speed is lower than a number will appear this phenomenon. Everybody will consider there is air in the system, and maybe the pump oil has pulsed, the valve control frequency stability is not enough.

On one hand, hydraulic cylinder seal leakage. Because seals were wearied after long time working, or the cylinder and rod were wearied. From this point, the seals with best quality is very significant.

On the other hand, hydraulic cylinder creeps. The reasons are the valve is too small, or the designed rod speed of the hydraulic cylinder is slower and flow is small. Even though the valve is fit, the hydraulic cylinder speed is lower than a number will appear this phenomenon. Everybody will consider there is air in the system, and maybe the pump oil has pulsed, the valve control frequency stability is not enough.

Creep is a frequently phenomenon appeared in hydraulic transmission and it is abnormal. Slight creep will result in machine shakes; this phenomenon naked eye is very in cognizable. But prominent flow will produce beats and a big distance movement. Creep phenomenon is not a good thing, so it is very important to eliminate creep phenomenon to improve hydraulic system stability and machine tool precision.

Kewords :

The Exhibition is drawing near, HC made a full range of preparatory work to meet the exhibition, HC not only prepared a high-quality products, professional service, but also prepare a large number of brochures distributed to the scene of the customer . HC will be high quality, high service's image appears on the Exhibition.

Kewords :

Any brand of goods have one or more agents all over the world, including HC. An agent not only can supply products immediately, but also can supply service according to customers requests.

And up to now, HC got some agent to give service to some country. But these are still not enough. Our goal is getting in touch with customer in the first time, in order to solve problems as soon as possible.

As is known to all, HC hydraulic cylinders quality is excellent and price is very reasonable, the prospect of the products is very good. If anyone of you are interested in our products, PLS do not feel hesitate to contact us soonest, you may assured that best service will be offered.

And up to now, HC got some agent to give service to some country. But these are still not enough. Our goal is getting in touch with customer in the first time, in order to solve problems as soon as possible.

As is known to all, HC hydraulic cylinders quality is excellent and price is very reasonable, the prospect of the products is very good. If anyone of you are interested in our products, PLS do not feel hesitate to contact us soonest, you may assured that best service will be offered.

Kewords :